Additive Manufacturing Solutions

Services

Research and Development

Have a research project? Look no further than us. We are happy to assist in any R&D assignments thrown our way, and will deliver as many parts and perform as many trials as you need. Have any doubts? Feel free to view our list of past and present research partners!

Fabrication

We strive to produce the highest-quality products on the market. We offer a variety of different fabrication tools and methods, such as friction stir welding, deep metal drawing and stamping, as well as laser welding.

Training

Training new employees is something we love to do. Whether it’s training on a specific machine or software, or simply learning about the industry, we are eager to assist in the process.

Interested? Contact Us! (LINK HERE wHEN CONTACT PAGE IS FINISHED)

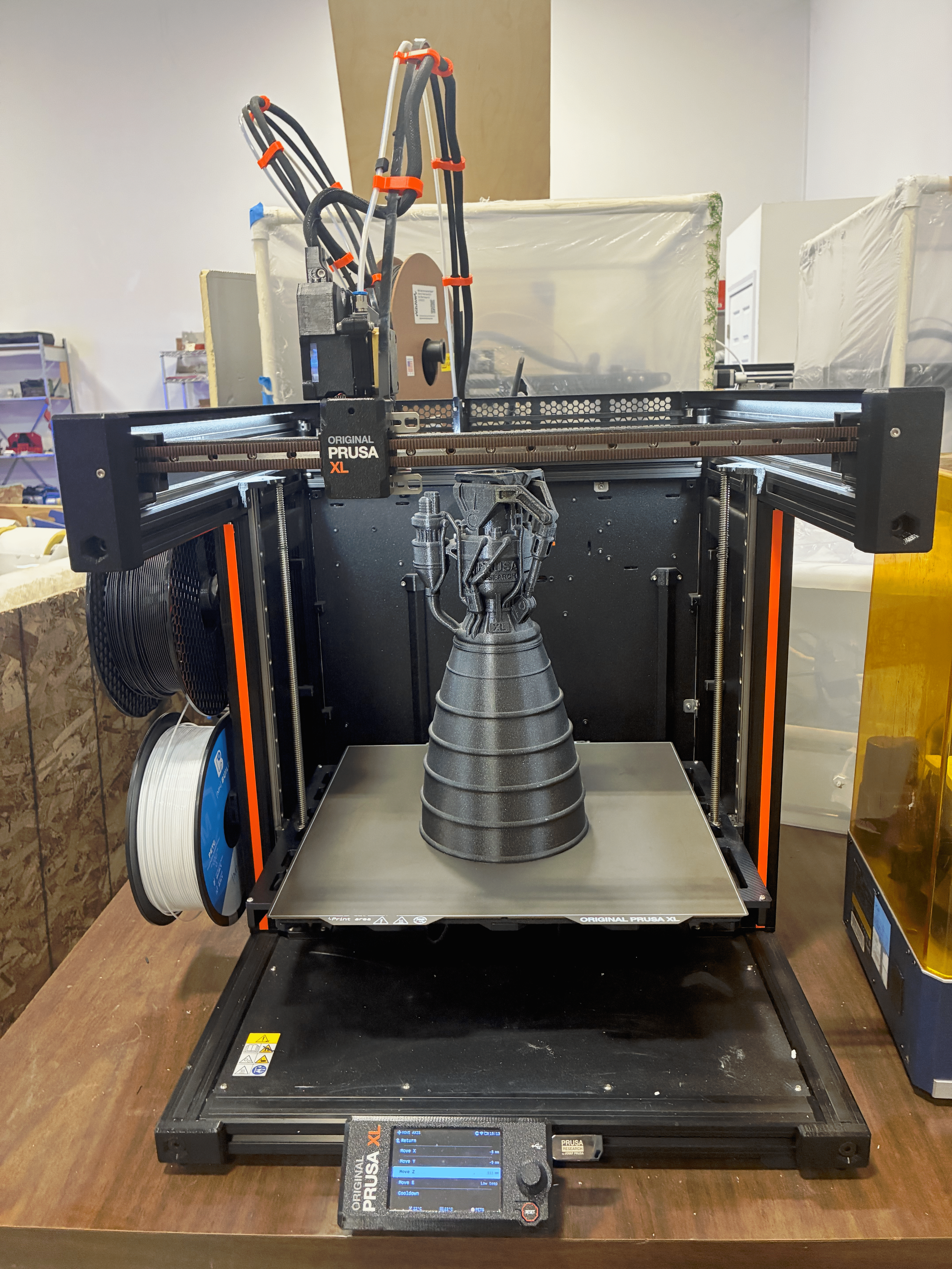

Machines

Pictured: Robot Type FSW Machine, CNC Type FSW Machine, Gantry Type FSW Machine, Original Prusa XL 3D Printer, Cobot-Assisted Assembly Line, Electro-Chemical Reactor

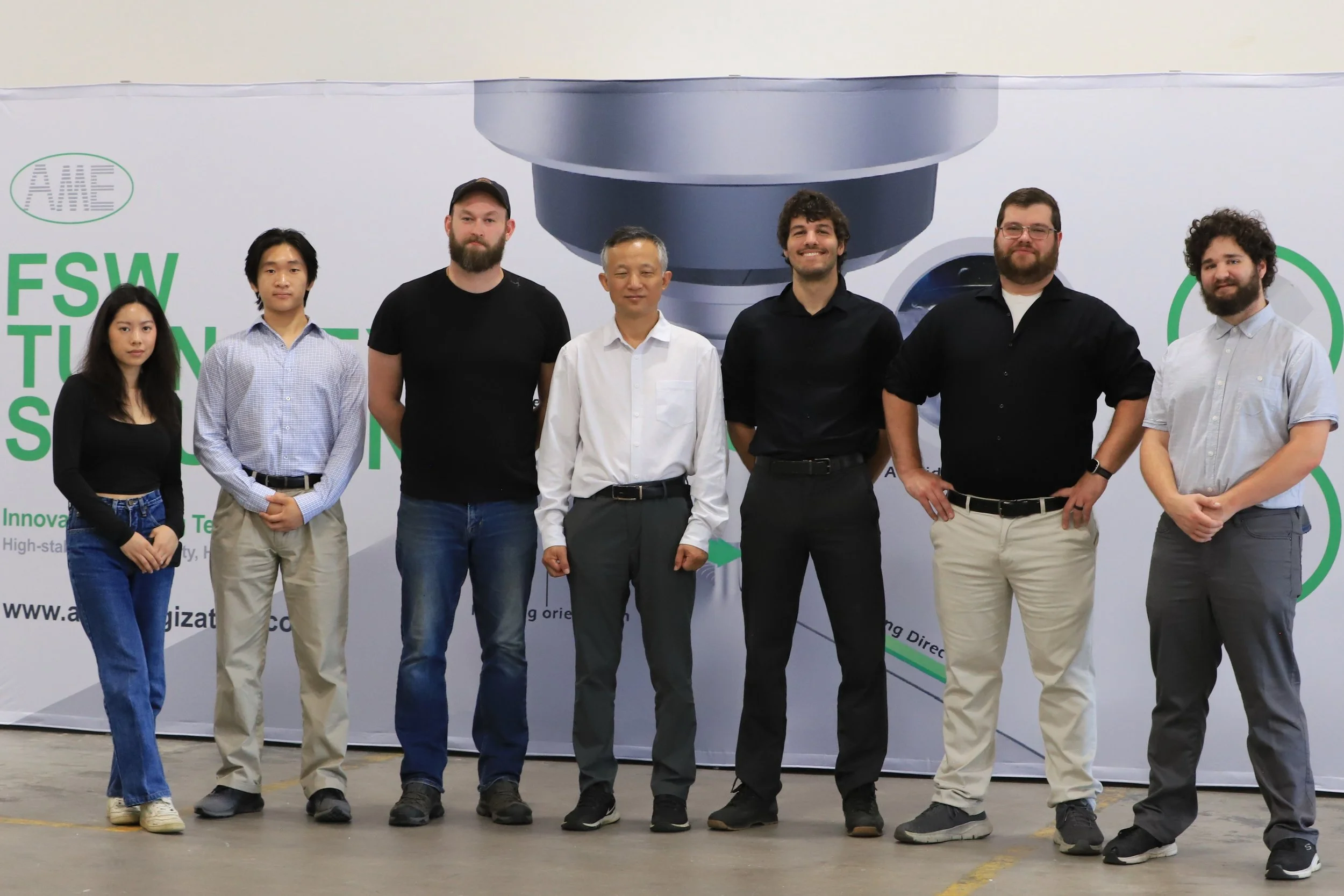

About AMLLC

Identifying the opportunity of additive manufacturing in the aerospace industry, Dr. Dongsheng Li moved into this field to promote the advancement of novel technology. Without the limitations and delays of bureaucracy, AMLLC has the freedom to help clients implement their ideas with previously unseen efficiency.

AMLLC has worked with the aerospace, automobile, and energy industries to advance additive manufacturing. AMLLC also highly appreciates the funding support from the Department of Energy, the Department of Defense, NASA, and the state of Connecticut.

Why Us?

Every machine provider will tell you that theirs is best. As an independent third-party evaluator, we will provide a one-step solution to your manufacturing upgrade plan based on your product list and utility capability. Which additive manufacturing machine will fit your needs?

To maximize the benefit of additive manufacturing, we redesign most parts since the limitation of manufacturability is removed in the arena of additive manufacturing. We provide design optimization for clients based on load analysis, life operation cost, and manufacturing cost.